Types of Laser Markers for Aluminum

You can use different types of laser markers on aluminum, including:

Laser engraving entails using a laser to remove or alter a material’s surface in a targeted area to leave a permanent mark. This process is an excellent way to leave lasting marks on aluminum, a material popular in aerospace, construction, automotive and other industries.

Telesis Technologies, Inc. provides safe, durable equipment for laser engraving aluminum. We use our Merlin® software and robotic integration, to achieve streamlined processes. By designing efficient tools and being committed to quality, we produce equipment that delivers precise results.

Contact UsLaser engraving offers several benefits for operations that often work with aluminum:

This process achieves high-contrast, permanent markings with increased readability.

When laser engraving aluminum, you can easily achieve deep markings that other materials don’t allow.

The rapid marking capabilities you get with laser technology support high productivity.

Laser marking equipment requires minimal maintenance and zero consumables, making it cost-effective.

Laser engraving aluminum achieves deep, precise markings for legibility that will last.

Once you engrave aluminum, the markings resist wear, surface treatments and high temperatures.

Aluminum laser etching machines are useful in industries ranging from electronics to mechanical engineering to tool manufacturing. You can laser engrave aluminum for any of the following applications:

Serial Numbers

Barcodes

Logos

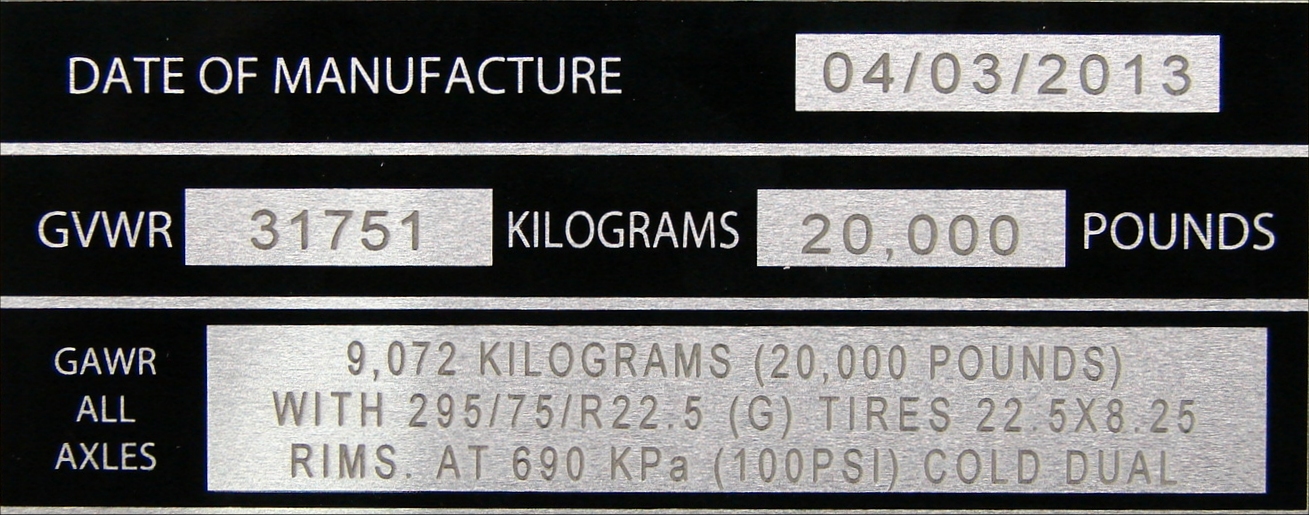

Data Plates

Expiration Information

Casings

Fuel Filters

Flash Drives

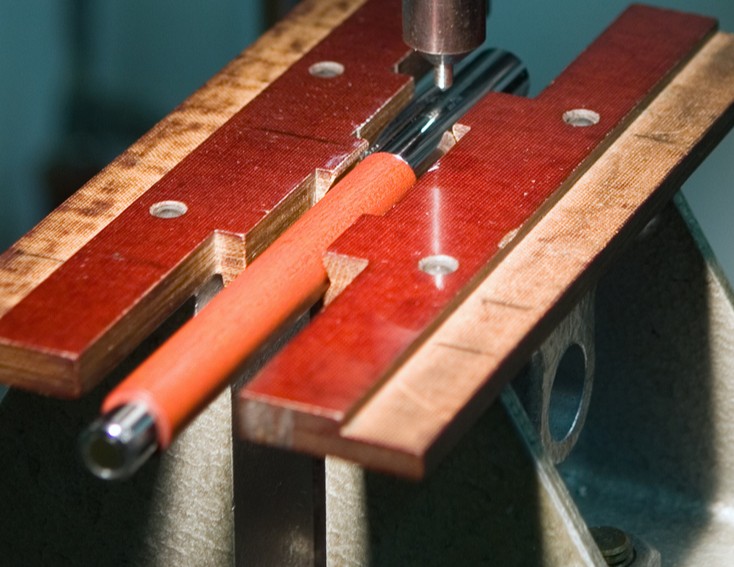

Customized Pens

Keychains

You can use different types of laser markers on aluminum, including:

Vanadate markers provide impeccable beam quality and are most suited to marking heat-sensitive materials.

These markers use diodes to radiate light, which they then transfer to fiber optic cables to form a laser beam. Bare metals like aluminum are ideal for fiber laser markers.

Dual-head laser markers are synchronized and feature two laser markers that can be operated with one controller.

They are an excellent choice for rapid aluminum processing.

These markers are capable of cold marking and work well on delicate substrates.

These markers work best on high-reflectance metals, as they use absorbent wavelengths that remove heat stress.

Telesis has VIN systems placed over 25 years ago still operating today – the longevity of our systems are matched only by our ongoing service and support of our global corporation that is part of every marking system sold by Telesis.

Mark up to six characters per second with the TMM5100 Multi-Pin Marking System. Its lightweight, compact design, and minimal footprint are ideal for hand-held, stand-alone or completely integrated, factory automated operations.