The Importance of Laser Marking for Medical Equipment

A laser marker for the medical sector enhances accountability and leads to manufacturing innovation. Identifying specific equipment concerning patient outcomes could lead to improved designs and approaches to care.

Laser marking also contributes to:

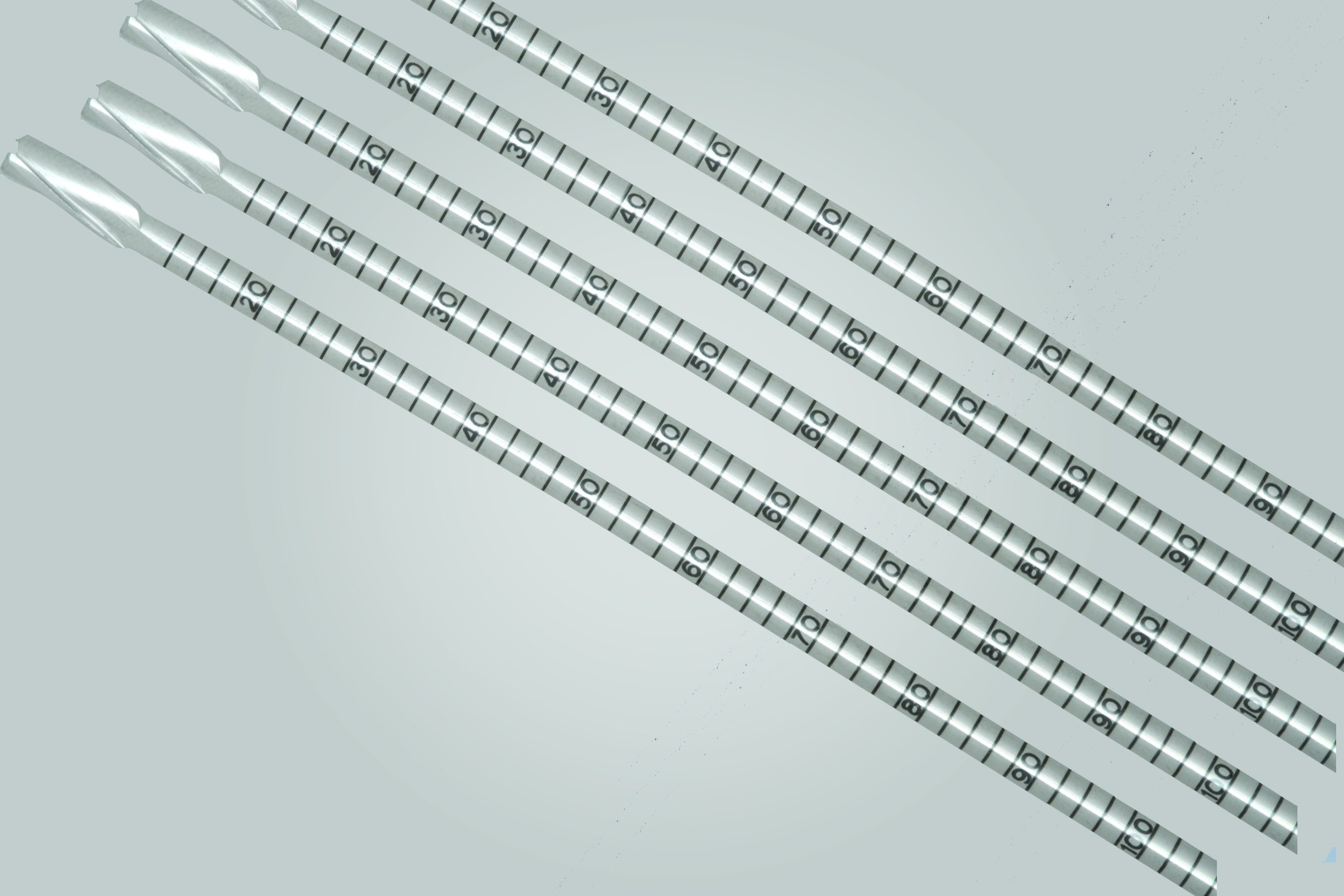

- Compliance with regulations: The FDA oversees the Unique Device Identification System (UDI System). Manufacturers must engrave all medical equipment, including instruments, tools and devices, with clear, legible and permanent markings.

- Enhanced patient safety: Laser marking can reduce errors and streamline post-market surveillance and traceability. With easier identification, medical professionals and manufacturers can monitor adverse events, manage risks and make more informed decisions.

- Recall response planning: The medical industry is highly regulated for patient safety. Should anything happen with your original products, you have maximum oversight over your offerings. Understand which of your medical tools or technologies require further action during an emergency.

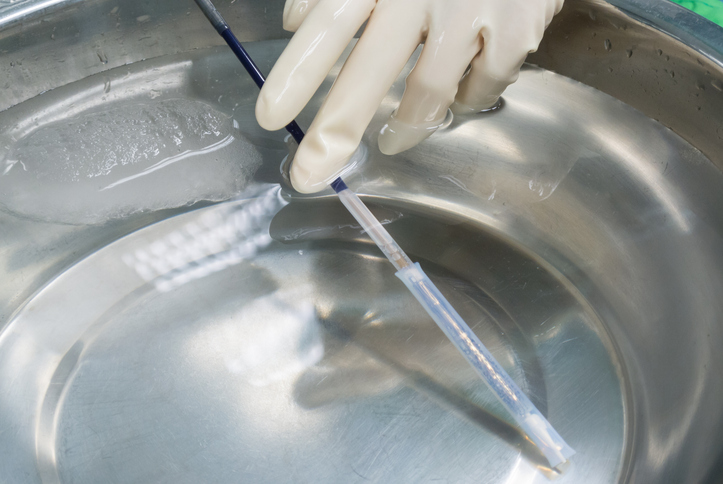

- Clean manufacturing practices: Laser marking for medical devices removes the need for printed labels and ink. This allows you to manufacture more specialized equipment that must undergo sterilization practices before use. Feel confident that chemical and liquid exposures will not tarnish markings.